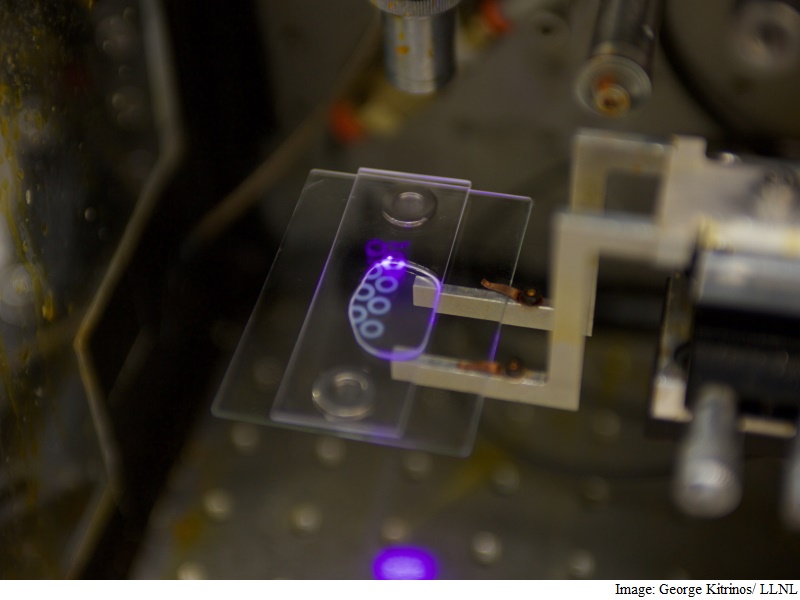

Scientists have combined 3D published polymers with methane-eating micro organism to create the firstreactor that can produce methanol from the greenhouse fuel, an strengthen which could result in a extragreen electricity manufacturing.

The researchers removed enzymes from methanotrophs, bacteria that eat methane, and blended them with polymers that they revealed or molded into innovative reactors.

“Remarkably, the enzymes maintain up to one hundred percent pastime inside the polymer,” said Sarah Baker, from the Lawrence Livermore countrywide Laboratory inside the US.

“the broadcast enzyme-embedded polymer is quite bendy for future development and should be useful in a wide variety of programs, particularly the ones involving gas-liquid reactions,” Baker said.

Advances in oil and gas extraction strategies have made significant new shops of herbal gas, composedtypically of methane, to be had.

A big quantity of methane is leaked, vented or flared in the course of those operations, partly because thegasoline is difficult to save and transport as compared to extra–precious liquid fuels.

Methane emissions also contribute about one-0.33 of modern-day internet worldwide warmingcapability, on the whole from these and different disbursed resources inclusive of agriculture and landfills.

present day commercial technology to convert methane to more treasured products, like steam reformation, operate at high temperature and pressure, require a massive wide variety of unit operations and yield a range of products.

The handiest recognized catalyst to convert methane to methanol below ambient conditions withexcessive performance is the enzyme methane monooxygenase (mmorpg), researchers stated.

The reaction may be accomplished with the aid of methanotrophs that include the enzyme, however thismethod inevitably calls for strength for maintenance and metabolism of the organisms.

as an alternative, the team separated the enzymes from the organism and used the enzymes without delay.

The team found that isolated enzymes provide the promise of particularly controlled reactions at ambientconditions with better conversion performance and extra flexibility.

“to date, most business bioreactors are stirred tanks, which can be inefficient for gas-liquid reactions,”stated Joshuah Stolaroff, an environmental scientist on the team.

“The idea of printing enzymes right into a strong polymer shape opens the door for new styles of reactors with tons higher throughput and decrease strength use,” said Stolaroff.

The team determined that the 3-D–printed polymer will be reused over many cycles and used in betterconcentrations than feasible with the traditional approach of the enzyme dispersed in solution.

The research was published inside the magazine Nature Communications.

download the devices 360 app for Android and iOS to stay updated with the modern day techinformation, product opinions, and specific offers on the famous mobiles.

Tags: 3-D Printing, Carbon Compounds, Methane, Methanol, science